Back coating machine for woven carpets

BEJIMAC back sizing machine is considered as a leading machine for high efficiency and reliability back coating

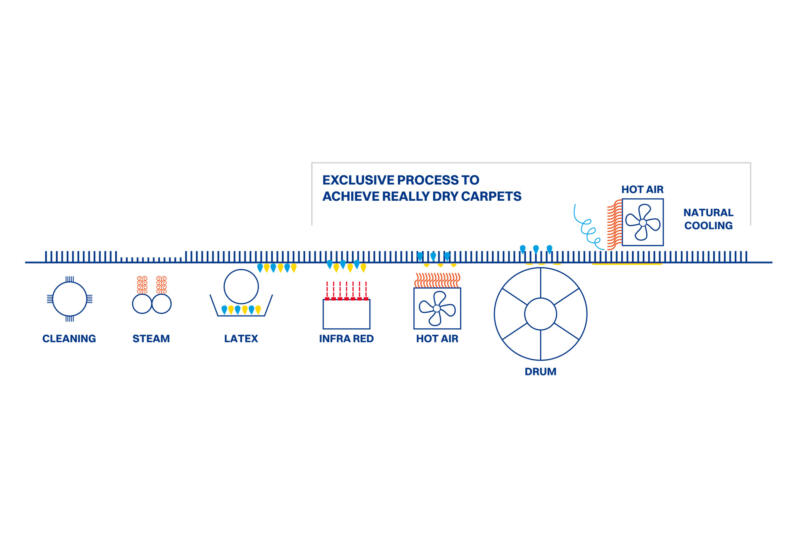

A lot of continuous technological developments make the BEJIMAC machine always a step forward. In addition to that, we also make the difference with our exclusive process to achieve really dry carpets

Here are in a few words some practical points concerning our back sizing machine:

- For carpets up to the widest width, with a maximum speed of 14 m/min

- Constant quality – Full automatic system reducing operators’ intervention, increasing quality and production

- Complete video surveillance for operators and offices

- recipes for the process production management system

- High efficiency cleaning reducing dust in the latex area

- Easy communication between machine operators, and optimisation of the space thanks to the location of carpet feeding and delivery in a close proximity

- Weft straightener correcting weaving distortions in the design

- Shrinking system for the process of bulk acrylic fibers

- Constant quality of the glue thanks to its automatic preparation

- Automatic cleaning of the pipes and tanks

- Automatic width detection and lateral guiding

- Integrated system for easy cleaning of the sizing area

- Bejimac exclusive passage taking care of the pile during the process

- Automatic carpet tension regulation

- No residual moisture in the carpet

- Application of 2 different glue types (simultaneously or separately) with kissing roller

The BEJIMAC modular concept allows to meet all production requirements.

The back sizing machine can work:

- As a single machine (cleaning included)

- In a complete line including cleaning, back sizing and shearing

Questions?

Submit your data and you will be contacted by one of our experts