Shearing machine for carpets

We usually provide shearing machines from one to three heads, depending on your production capacity.

Considered as the leader in carpet shearing and being part of Vandewiele, BEJIMAC always brings new developments to the market

The most recent development made in shearing by BEJIMAC & Vandewiele is the new autonomous shearing machine (the ATSH).

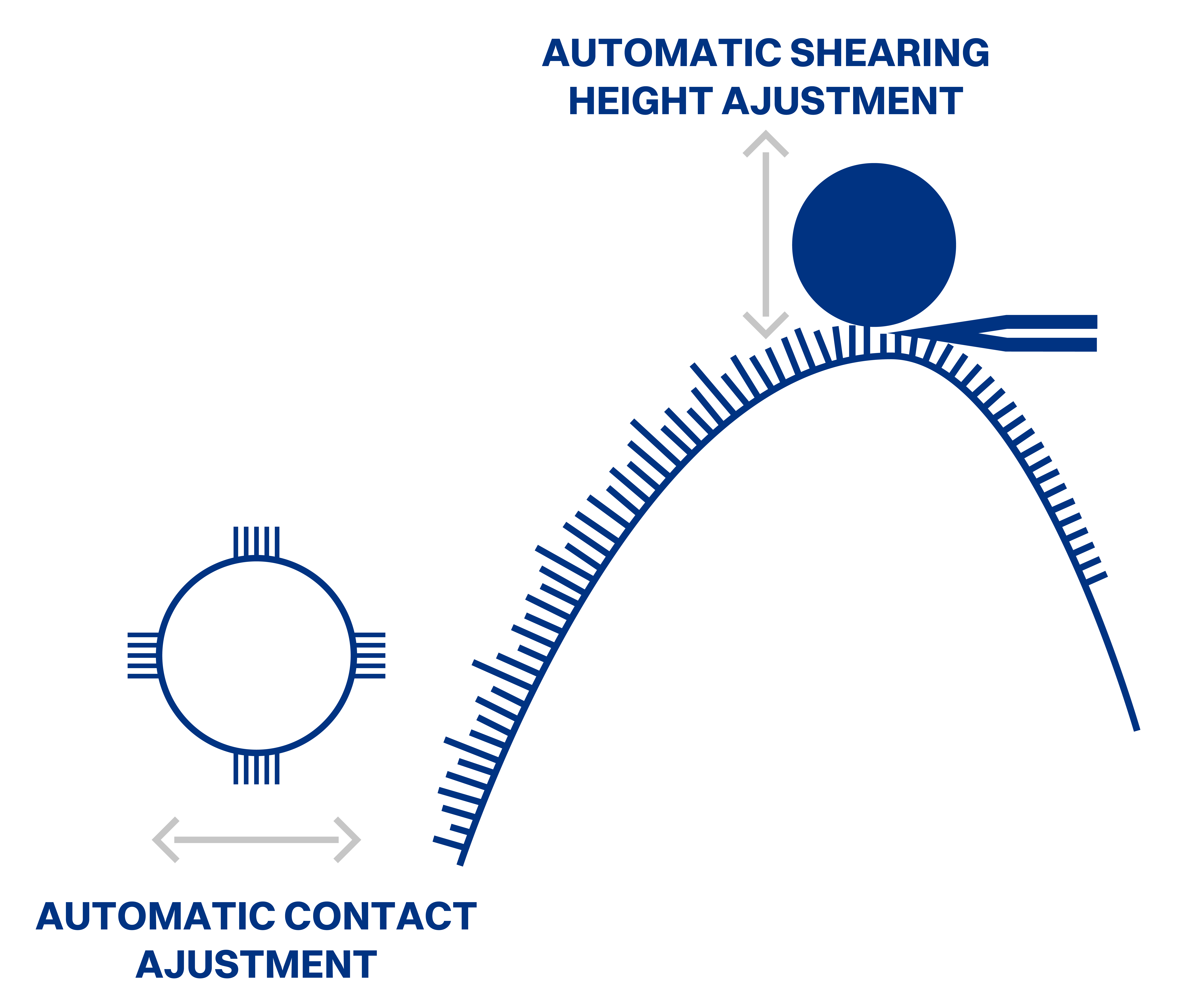

This machine is the first shearing machine able to automatically adjust the shearing height, operation very much depending on experienced and qualified operators.

This is the result of high level engineering works and trials done in the Vandewiele Experience Center.

The machine indeed makes continuous checks of the height before and after shearing. We have developed algorithms to interpret these data and make the right adjustment decision.

A lot of parameters are to be taken into account.

Additionally, we have replaced hydraulics by servomotors for setting the shearing height even faster and with a better accuracy.

Finally, a lot of continuous improvements were added to these new developments.

Here are in a few words some practical points concerning our shearing machine:

- For carpets up to the widest width, with a maximum speed of 20 m/min. Higher speeds can be reached for tufted carpets.

- Constant quality with our full automatic system reducing operators’ intervention, increasing quality and production

- Protection of shearing head by metal detector and seam detection

- Automatic tension regulation whatever the carpet type

- Electrically driven transparent protection guard

Some examples of the results of the technology developments made to continuously tighten to the best surface treatment possible:

- Suitable for different carpet back constructions

- No stripes

- Suitable for different carpet fibers

- Finer appearance (300 mm diameter, up to 600 RPM)

- No Moiré

- Clean finished carpets

Ergonomics

- Quality programming

- Running of each head from all touchscreens

- Parameter history

- Synchronization with other BEJIMAC machines

Maintenance

- Maintenance recommendations

- Easy cleaning of the shearing head

- Electric grinding equipment

Submit your data and you will be contacted by one of our experts