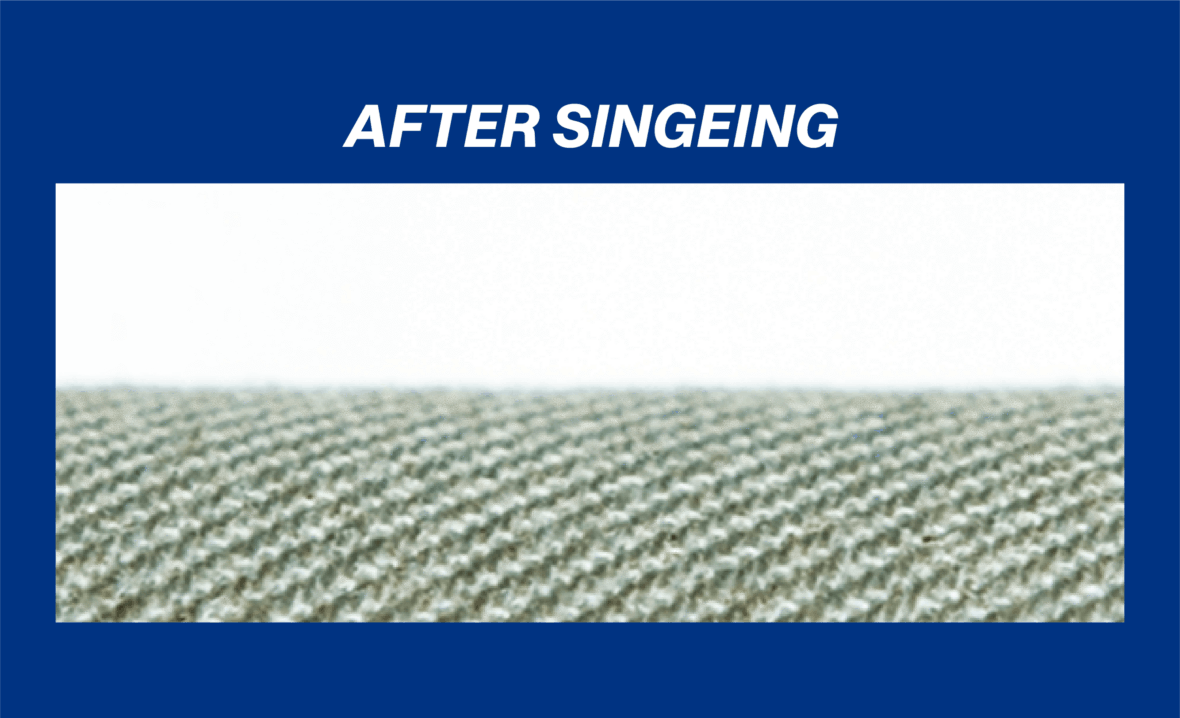

Singeing machine

Our singeing machine is known for its flexibility, lower gas consumption with great performance

In addition to being the leader in carpet finishing, BEJIMAC gathers a huge experience in singeing with long term satisfied customers

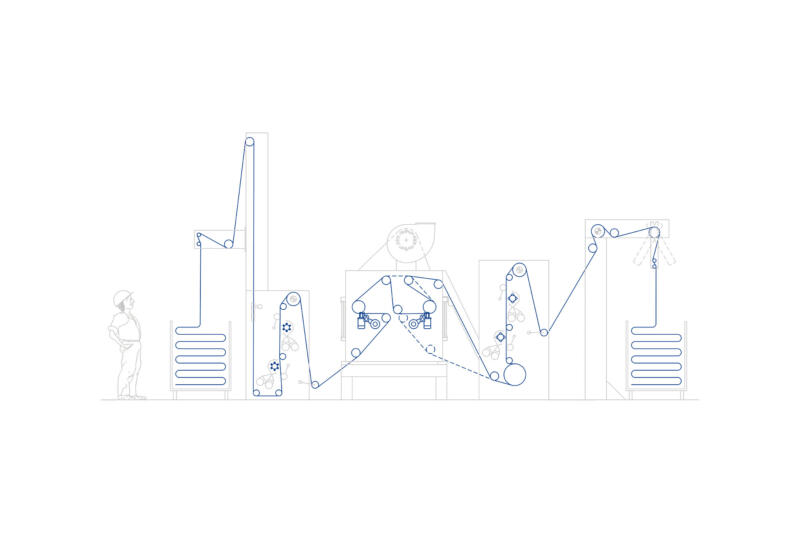

For the process of woven fabrics, our singeing line has a modular design with such options as

- Different types of entries

- Brushing (single or double)

- Singeing (with 1, 2 or 3 burners)

- Beating (single or double)

- Dust collection

- Desizing

- Squeezing

- Different types of exits

These options allow each customer to select only the necessary modules which are required by his particular factory.

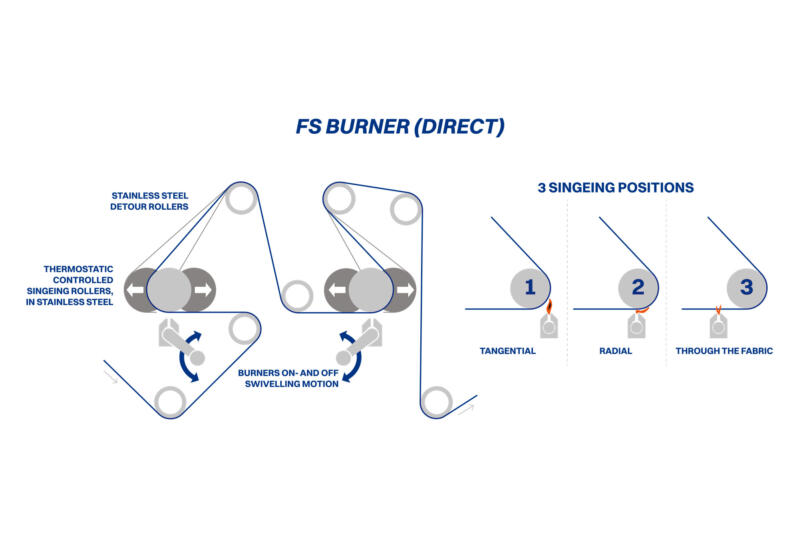

Our FS direct flame bruner ensures the full regularity of the flame over the whole width of the fabric. Each burner can be adjusted independently in three singeing positions (, radial or tangential), and so, it is suitable for any type of fabric (natural fibres and blends).

- Through the fabric

- Tangential

- Radial

And so, it is suitable for any type of fabric (natural fibres and blends).

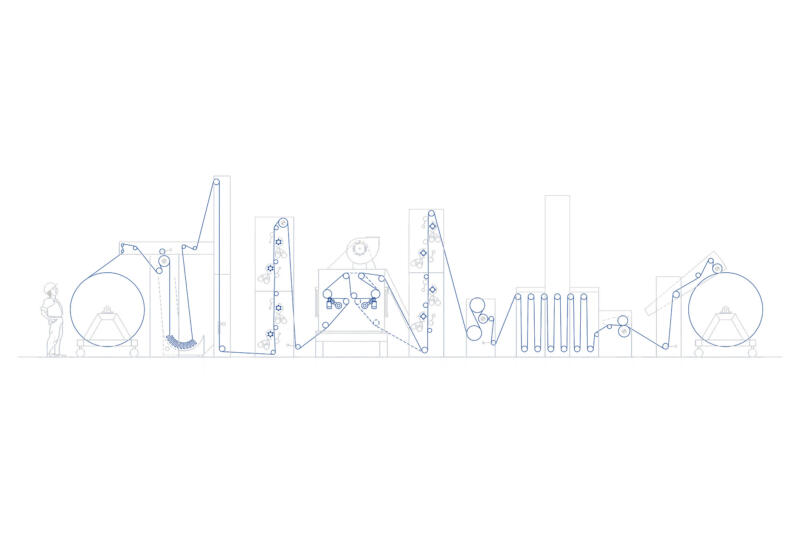

For the process of woven fabrics, our singeing line has a modular design with such options as

- Different types of entries

- Brushing (single or double)

- Feed-in unit with optional J-Box, for continuous process and driven cylinder for regular feeding through the singeing module.

- rushing module for removal of the dust by means of dust collectors with a slot covering the full width of the fabric. The achieved result is beyond expectation compared to the extraction from, a closed frame. For very dirty fabrics, we can supply this module with 4 brushes.

- Water cooled cast iron burners (FS4 model), without expansive ceramics to be replaced regularly. No maintenance cost and continuous top quality flame.

- Beating module, for removal of the dust by means of dust collectors with a slot covering the full width of the fabric. The achieved result is beyond expectation compared to the extraction from, a closed frame; it is also fitted with a stainless steel cyclone and a pneumatic sas for a maximum security and a continuous perfect suction at the two beaters. For very dirty fabrics, we can supply this module with 4 beaters.

- Cooling unit before going into the impregnation vessel to supply the necessary basis for the accurate control of the liquor temperature and to avoid the mechanical deterioration of dome fibers, especially for technical fabrics.

- Desizing department: no other desizing module has so much advantages that the Bejimac one.

- Switch from “wet to dry” or from “dry to wet” in a few seconds.

- Cleaning of the tank has never been so easy

- Plunged bearings without maintenance

Questions?

Submit your data and you will be contacted by one of our experts